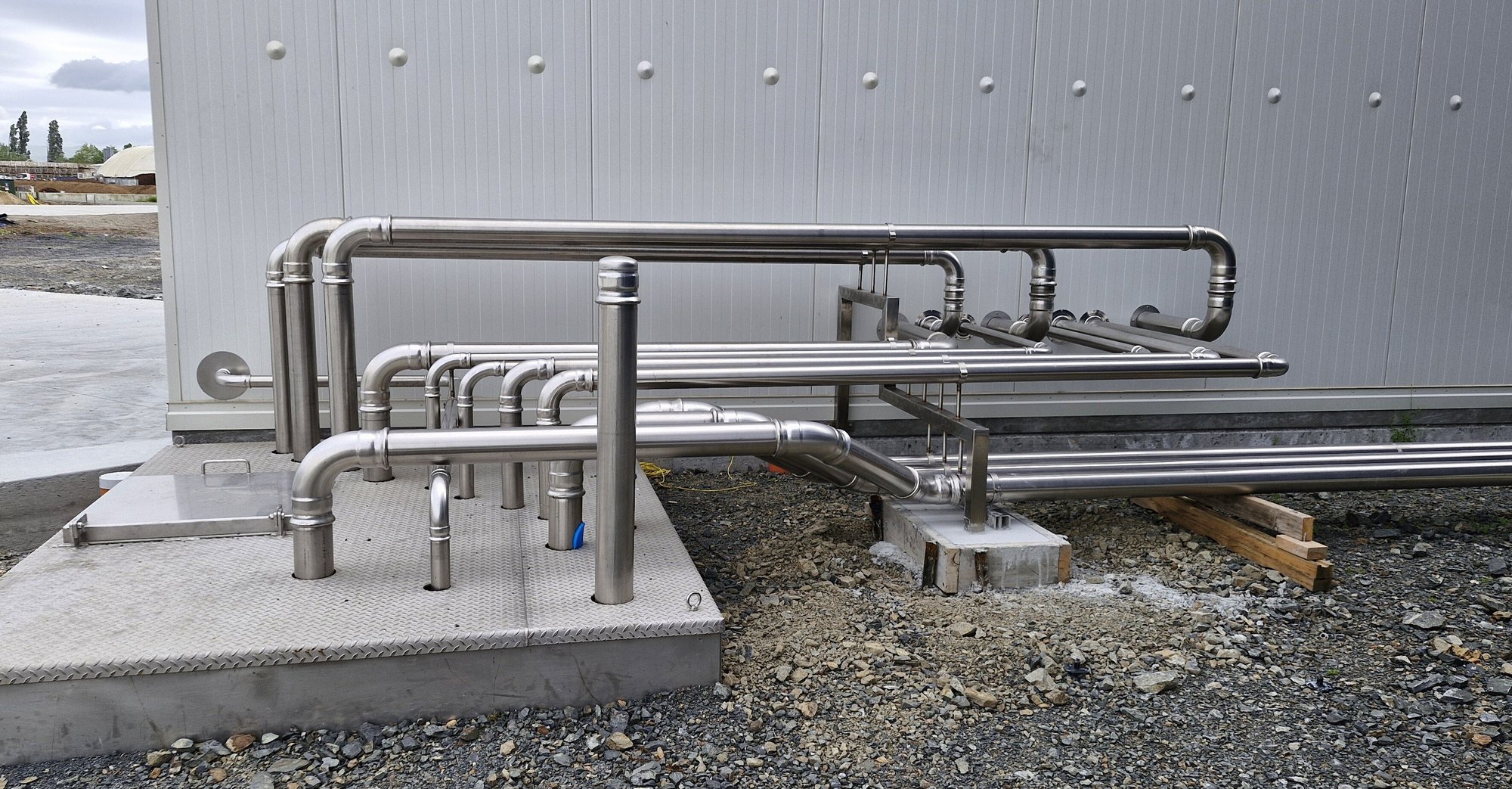

Water Treatment Plant at Waitoa Protein Plant

Overview:

The Waitoa Protein Plant project involved the creation of a new facility designed to extract bore water from the ground and pass it through an extensive filtration system to provide clean water for the plant and its boiler. A "showroom finish" was required, necessitating all visible components to be made of Stainless Steel.

Supplied Materials:

Waterworks Supplied:

- Electrofusion fittings

- Approximately 200 meters of polyethylene pipework

- Europress fittings (15mm to 168mm)

- 1 km of Europress Tubing

- Bracketing

- A range of valves

- Sch.80 PVC

.png?width=2000&height=619&name=Untitled%20design%20(77).png)

1. The Challenge

◦ The primary challenge was the strict five-month timeline for this installation.

2. The Requirements

◦ To install a water filtration system that draws bore water from the ground and passes it through an extensive filtration system.

◦ A "showroom finish" was required, and all work was to be completed within a five-month deadline.

3. The Solution

Europress was selected as the preferred solution for this project due to...

1. Rapid installation capabilities, being up to ten times faster than traditional technologies. The installer highly recommends Europress for projects of this nature, as it significantly reduces installation time by eliminating the need for welding.

2. Its straightforward installation process and ease of bracketing.

3. Visually appealing design, ensured that the project met the criteria for a "showroom finish".

4. Key Benefits of working with Waterworks

"Waterworks made this time frame possible for us through a well oiled process from start to finish. Beginning with the website for ordering and the support from the team to fast reliable freight, topped off with good quality products that made success easy!"

.png)

Project Gallery