Pernod Ricard & Europress

One of New Zealand's leading wine, spirits and champagne companies, Pernod Ricard approached Waterworks in February 2017 with a situation that needed to be resolved urgently.

Pernod Ricard has storage tanks situated in Blenheim to hold the wine from their nearby vineyards.

Unfortunately, many of these weren't spared by the 2016 Kaikōura earthquake, and they were rendered unsuitable to hold the wine from the fast-approaching harvest.

The Challenge

Andrew Waller, Engineering Manager at Pernod Ricard needed to act fast as Beca was assisting them in designing a 28-tank extension to their Auckland tank farm to take up the slack from the Blenheim facility.

Andrew approached Waterworks about using the Europress press-fit piping system for glycol reticulation on the project, due to its popularity with other wineries.

New to the benefits of press-fit, Andrew wasn't sure if it would save them time and money over and against welding the pipework, so he split the glycol pipework for the first nine tanks between welded and Europress — awarding five tanks to a welding firm to install traditional welded stainless pipework, and four tanks to Steelcraft to install Europress.

The Tamaki tank farm also required nitrogen, water, and compressed air reticulation pipework in-tank additions.

The Requirements

A robust piping system for 28 wine storage tanks, that was:- As fast as possible to install with the quickly approaching harvest depending on the completion of the project.

- Competitively priced.

- Suitable for reticulation of glycol, nitrogen, water, and compressed air.

THE SOLUTION

Welded installation commenced around the 7th of March, and Europress installation on the 28th March. Ten days into the Europress installation, Jason from Steelcraft commented, "it was like a time warp" – the Europress installation was complete, and the welders were only just finishing their first tank!

Andrew compared the costs of the first nine tanks:

| Welded | Europress | Saving per tank | |

| Cost of glycol pipework per tank | $24,800 | $20,000 | 19.35% |

Europress savings and speed win Steelcraft additional work

_reduced.jpg)

KEY BENEFITS

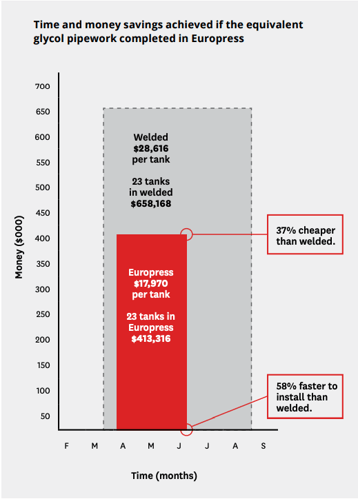

- Europress cost 37% less than welding was projected.

- Europress was 58% faster to install than welding would have been.

- Was able to be installed in rainy conditions.

- The majority of the pipework was able to be modelled using Water Works' 3D drawings thus speeding up design, procurement, and installation.

- The system was fast to install, reducing labour costs and providing project savings.

- The rapid speed of installation meant the tank farm was ready for the harvest.

Specs

- Europress stainless steel press-fit pipe system.

- Transporting New glycol, nitrogen, water and compressed air.

- Pipe sizes include 3/4" (22mm) through to 4" (108mm) stainless steel.

The installation time proved to be less than half

"We had a very tight deadline to reinstate tanks following the 2016 Kaikoura earthquake in time for vintage and needed a rapid install of services piping for new tanks being installed at the Tamaki site.

A fully welded option wasn’t going to be acceptable due to the long install time. So, we trialled Europress piping on four tanks, which was completed simultaneously with five tanks that were welded.

The result showed that the Europress option was the way to go going forward, and so the remainder of the tank farm was completed using that. The installation time proved to be less than half that which was quoted for welded pipe install, and installed costs have come in at two-thirds that of welded piping.”

Andrew Waller, Engineering Manager at Pernod Ricard

What are your plant's values?

Talk to us about installing a durable system that will last the life of your plant and reduce project costs.